Roswell, GA – GS Yuasa Lithium Power (GYLP) announced today the successful completion of the Preliminary Design Review (PDR) for a new scalable small form factor battery design. With PDR complete the battery design will now move into the critical design phase.

GYLP’s design integrates the recently qualified LSE12x Lithium-ion Cell developed by GS Yuasa Technology LTD (GYT) and seeks to align with smaller spacecraft, including those with high power requirements and those supporting human rated missions. The flexible approach accommodates 16 to 96 cells (720Wh to 4320Wh nominal) and can be electrically configurated to support both low and high voltage bus applications.

“GS Yuasa leads the industry with more than 4.4MWh of Lithium-ion energy storage flown in space,” said Curtis Aldrich, President of GS Yuasa Lithium Power. “Our customers demand outstanding performance, reliability and value. With the introduction of a 12Ah cell and GYLP’s forthcoming scalable battery design, we’re bringing the attributes responsible for our success in medium and large spacecraft to a solution that can be optimized for smaller spacecraft.”

Cells and batteries will be fully configuration controlled and built to AS9100 Aerospace Quality Standards with an auditable manufacturing and change record. This approach mitigates the need to repeat the full qualification and life performance test for each new production lot. End-users can verify the materials and processes employed remain consistent lot to lot. This provides our customers a significant reduction in program testing costs compared to other similarly sized solutions.

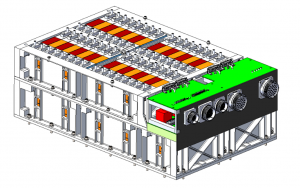

The next milestone will be the completion of the Critical Design Review (CDR) which will address the battery configuration identified for our internal qualification program. The qualification model is a 72-cell configuration wired as an 8s9p battery (30Vnom 108Ah, 3240Wh). This configuration incorporates all manufacturing and inspection processes present on smaller and larger configurations. A full qualification test suite is planned including environmental survivability.

8s9p LSE12x Qualification unit with connector box (cover and inter-cell connects not shown)

The design approach for the 72-cell battery seeks to optimize the volumetric packing efficiency while providing robust survivability for the majority of the available launch vehicle dynamic environments. Thermally the battery is designed to reject heat by conduction through a baseplate tied to the host vehicle’s thermal management system. Connector interface is flexible and can be tailored to match each vehicle’s specifications. Battery monitoring and available telemetry will also be tailorable with options for temperature monitoring points, individual cell or mid and full stack voltage reporting, as well as redundant heater options.

Fault tolerance and anomaly mitigation have also been carefully considered. In the unlikely event of a cell fault, each 8-cell string can be isolated in the battery through a commandable relay. Using the battery telemetry, the satellite operator is able to detect the event and issue a command to clear or isolate the fault.

The battery design includes provisions to mitigate propagation of a thermal runaway event and to collect and direct effluent material. Although a thermal runaway event is extremely unlikely, it is best to manage the effect on both safety and continued operation. For human rated missions subject to the requirements outlined in JSC20793, such provisions are mandatory. GS Yuasa Lithium Power has recently been awarded a US patent for systems and methods relating to effluent containment.

About LSE Cells

First introduced in 1998 the “LSE” Li-ion cells were specifically designed for the unique environments and demanding duty cycles of aerospace applications. For more than 20 years, GS Yuasa space cells have earned a reputation for delivering exceptional performance and value in critical commercial communication, remote sensing, scientific, defense and human rated applications. With volumes of life and performance data available and a solid connection between industry leading spaceflight heritage without failure and the Li-ion cells offered today, GS Yuasa’s value proposition is stronger now than ever.

About GS Yuasa Corporation

GS Yuasa Corporation was established in 2004 by the merger of Japan Storage Battery Co., Ltd and YUASA Battery. GS Yuasa develops and manufactures batteries and power supply systems for a wide range of special applications. The company’s high-performance, high-quality batteries are installed in sea, land, and aerospace environments, from depths of 6,500 meters below the ocean surface to 36,000 kilometers in space.

http://www.gs-yuasa.com/jp/ (Japanese)

https://www.gs-yuasa.com/en/ (English)

About GS Yuasa Technology, LTD (GYT)

GS Yuasa Technology is a subsidiary of GS Yuasa Corporation located in Kyoto, Japan. GYT designs and manufacturers large format lithium ion cells for aerospace and specialty applications.

1-37 Osadano-cho Fukuchiyama-shi

Kyoto pref. 620-0853, Japan

Phone: 81-773-20-2630

About GS Yuasa Lithium Power (GYLP)

GS Yuasa Lithium Power, Inc. is the United States subsidiary of GS Yuasa focused on large format lithium-ion battery system manufacturing for US customers. Primary products are lithium-ion battery systems for aerospace, undersea, and defense applications. https://gsyuasa-lp.com/